The following article was sent to me by Finn Featherfurd and I thought it was interesting as it covers a reel manufacturer that very few people know much about--Feurer Brothers. When Bob Halver was finishing his amazing book on Airex/Lionel fishing tackle, I did a little research and dug up a few interviews and histories of the Feurer Bros., who took over much of the Airex line in 1964 when Lionel got out of the tackle business.

This article appeared in the July 1964 Fishing World magazine, and was written by outdoor writer "Big" Bill Wisner. It covers some fascinating history just around the time Feurer Bros. was taking over the Airex line. Note the ad at the end of the article carried two former Airex reels. Here is the text and photos.

I first encountered Roger and Walther Feurer in Chicago at the Fishing Tackle Manufacturers Trade Show. Two more genuinely friendly people I couldn't want to meet. I also was taken with their FB reels, and I was impressed enough with a description of their manufacturing techniques to make a trip to the FB factory in White Plains, New York.

It's for the creation of timepieces and watch movements, of course, that Switzerland is most famous industrially. Most of the world's finest watches--Omega, Gruen, Rolex, Patek Philippe--carry Swiss works. And therein, in the incredibly precise machining of watch parts, like a kind of bridge which spends the Atlantic between Switzerland and the American fisherman.

From their native land, the brothers Feurer brought an almost incredible personal accumulation of experience in the manufacture of watch parts. Their original machinery was designed to make components for watches like Hamilton, Movado, Omega, Elgin and others. Some years ago, however, these two fishing enthusiasts decided to put the same kind of precision machining that makes a Hamilton last a hundred years into what they preach are the world's finest fishing reels.

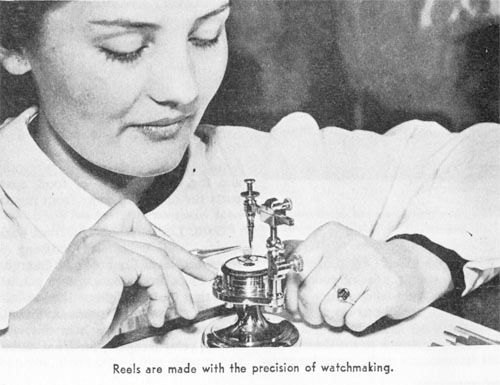

Up at White Plains, I watched FB reels being made from start to finish, progressing from raw metal stock through to the shipping room. I won't detail the dozens of steps involved; suffice it to say that the care taken to guarantee a perfect unit is enormous.

In the quiet, unhurried atmosphere I could feel that everyone was taking the time to be exacting.

For castings, the brothers Feurer use aluminum. Components are stainless steel; pinion gears of bronze for toughness and durability. This is normal in high quality fishing tackle. But most important for the angler who wants a reel that will work right under all conditions and for years to come, the machining of the components is the secret of success…and machining to watchmakers' tolerances is something no other fishing tackle manufacturer in the world can offer.

One FB exclusive I do want to highlight here is the quadrant-type drag mechanism. It's a truly ingenious piece of work!

This FB quadrant brake has a double set of uses. In one it offers an infinite number of settings, from off to strong tightness. As such it can be brought into play as a standard drag and can be adjusted, lighter of heavier, as a fish is being played. In its other type of service, the brake can be shifted from standard performance to any desired preset strength (according to the pound-test rating of the line currently involved) by simply flipping a lever.

I probably could write many more words about the set-up of the brothers Feurer--for example, with 24 hours after receipt of your reel for service, it's been conditioned expertly and en route back to you!--but the proof of the pudding is in the eating. Get One!

It's a very cool article and full of information. To read more about Feurer Bros. history and their reels, check out Bob Halver's Airex book.

-- Dr. Todd

2 comments:

I have a Feuro Bros. Flip REEL #202. iT SEEMS TYO BE IN GREAT CONDITION AND WORKS GREAT, TOO. wHAT CAN YOU TELL ABOUT THE REEL?

Post a Comment